UNITED STATES HARBOR DEFENCES - USCG CABLE SHIP PEQUOT

|

Design & Construction of the

General Samuel M. Mills 1908-09 Ship Plans – National Archives and Records Administration Construction Photos – Independence Seaport Museum Archives, New York Shipbuilding records www.phillyseaport.org/library |

|

This page provides more detail about the U.S. Coast Guard Cable ship

Pequot during World War II.

It describes the

design and construction of the US Army mineplanter General Samuel M. Mills

later renamed the USCG Pequot. It was as the Pequot the ship carried

out vital harbor defense cable-laying program along the eastern seaboard

of the USA. Our main page for the USCG

Pequot provides extra

details about the ship, its crew, its purpose as well as links to our other

Pequot pages. Research and design by by Chip Calamaio and Richard Walding.

|

|

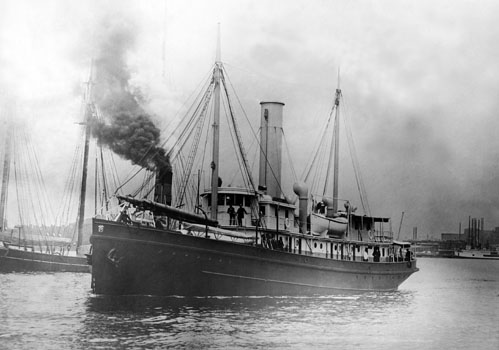

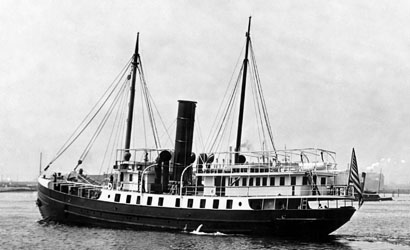

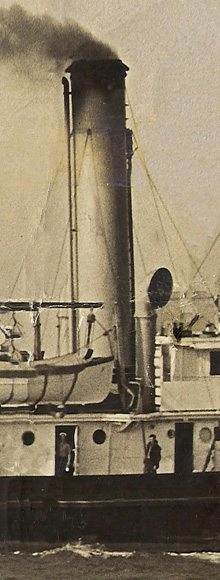

The US Coast Guard Pequot (previously The General Samuel M. Mills). During WWII this cable ship laid top secret Indicator Loop cables to protect harbors from German U-boats. Her mission ranged from the ports of Virginia up to Argentia, Newfoundland. (Calamaio family). |

THE BEGINNINGS

When the USCG

Pequot was built as the US Army mine

planter, the

General Samuel M Mills, she was constructed at the New York

Shipbuilding Company in Camden, New Jersey along with two identical sister

ships, the

General Royal T. Frank and the

General John. M. Schofield under a

contract with the Submarine Mine Service of the US Coast Artillery Corps which

was under the War Department, US Army, Office of the Quartermaster General. The

ship was named after Brigadier General Samuel Meyers Mills, Jr. who was the

U.S. Army’s Chief of Artillery 1905-1906.

|

|

|

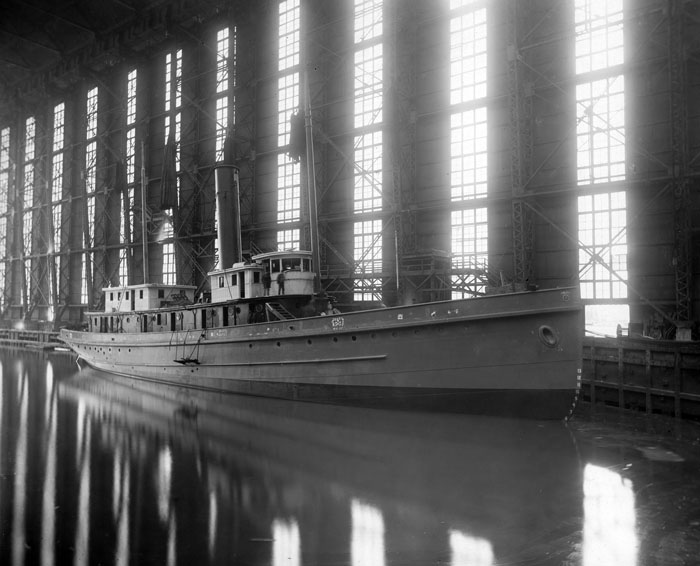

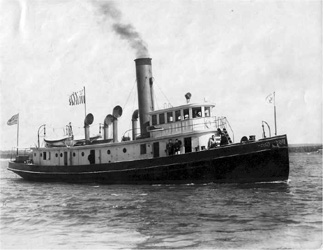

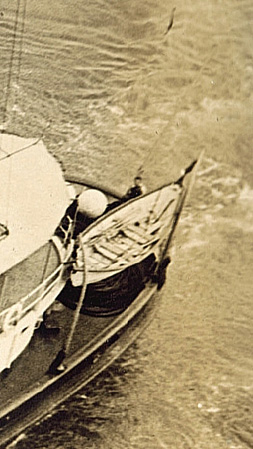

The

General

Samuel M. Mills during sea trials 1909.

|

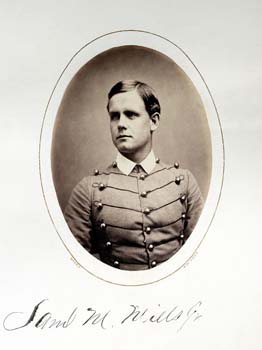

Cadet Samuel M. Mills in 1865 (Special Collections, US Military Academy Library, West Point) |

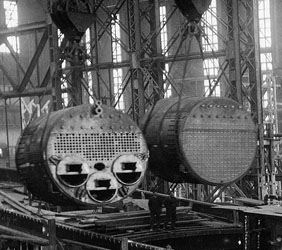

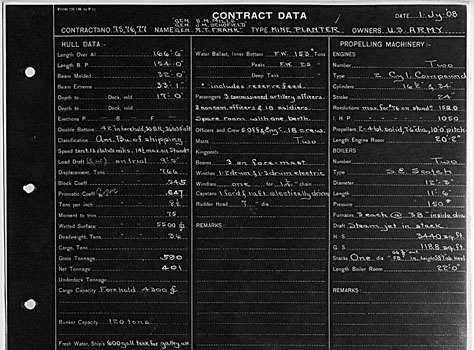

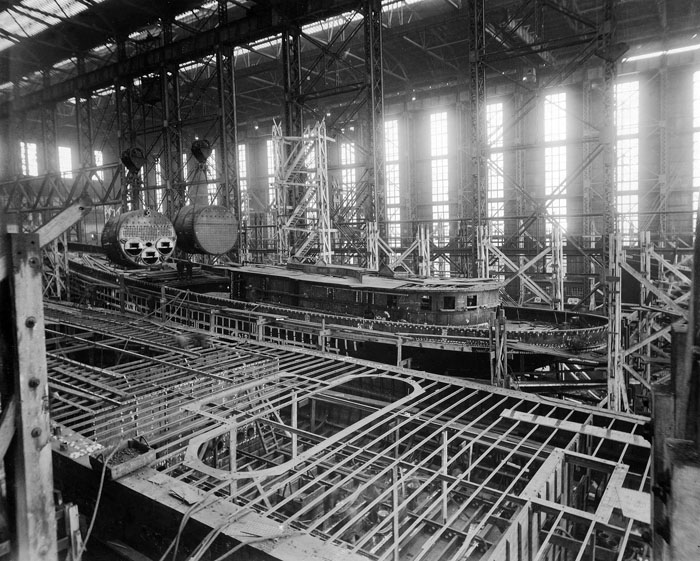

On July 1st 1908 contracts 75, 76 & 77 were awarded for three “Twin Screw Steel Steamers” which were built simultaneously under the huge covered shipbuilding ways K and L at Camden, off of the same plans, and to identical specifications. In fact the Mills and the Schofield both had their keels laid on the same day, October 12, 1908. Based upon what we’ve learned about the price tag for the Mills, the Army’s contract with New York Shipbuilding Company for these three ships in 1908 was approximately $900,000.

Located on a 160 acre site along the Delaware river across from Philadelphia, Pennsylvania the New York Shipbuilding company operated from 1899 to 1967. During WWII it was the largest and most productive shipyard in the world. Through the development of a revolutionary “template” system of building and prefabricating hull components for multiple ships to the same specifications at the same time, this technique pioneered by the company served American well during both world wars when ships of all types just couldn’t be built fast enough.

|

|

New York Shipbuilding company (A Place Called Yorkship / yorkship.us) |

The contract for the Mills, Frank, and Schofield was among the first order for multiple ships that used an enormous mold loft where hull plates were fabricated from templates in the cavernous covered shipways K and L. These covered sheds were equipped with enormous cranes which could lift 100 tons. These immense buildings were also used during this period to build many of the Navy’s huge dreadnought battleships which saw action during World War I.

|

|

| (Independence Seaport Museum Archives). | (Click to Enlarge). (Independence Seaport Museum Archives). |

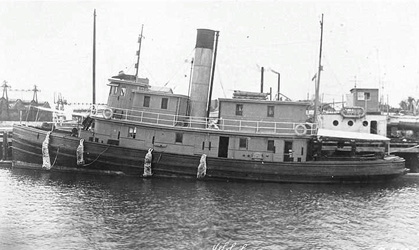

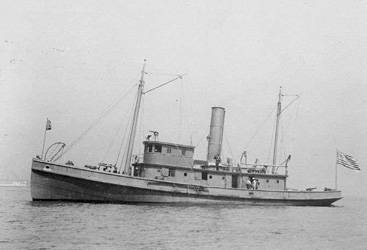

The era of naval architecture during which these ships were built can clearly be seen when looking at many small Coast Guard vessels and tug boats of the time. The design and lines of the General Samuel M Mills and her sister ships reflect the design influences of many these tall stack coal burning ships from the turn of the century.

|

|

| USCG Mackinac 1903. (Coast Guard Tug Association). | USS Saco in Port 1920s. (National Association of Fleet Tug Sailors). |

|

|

|

USS

Seminole

also Built in Camden, NJ. (National Association of Fleet Tug Sailors). |

USS

Vigilant July 1898. (National Association of Fleet Tug Sailors). |

|

|

| The New

York Shipbuilding Company built eight 190 foot Manzanita class

lighthouse tenders in 1907 for the U.S. Lighthouse Service. These

ships were being fitted out and completed right before

construction started on the Mills, Frank and

Schoenfield. Even though these lighthouse tenders where

slightly longer, had a larger upper rear cabin, and covered

gangways along both sides, the similarity of design to the Army

mine planters of 1908-09 is striking. In fact, in the Annual

Reports of the War Department for Fiscal Year Ended June 30, 1906

it was noted, by Arthur Murray, Lieutenant Colonel, Artillery

Corps, Commandant that, “...these planters are seagoing lighters

modeled after one of the latest types of Light-House Service

tenders, arranged, equipped and manned especially for mine work." (Independence Seaport Museum Archives - both images). |

|

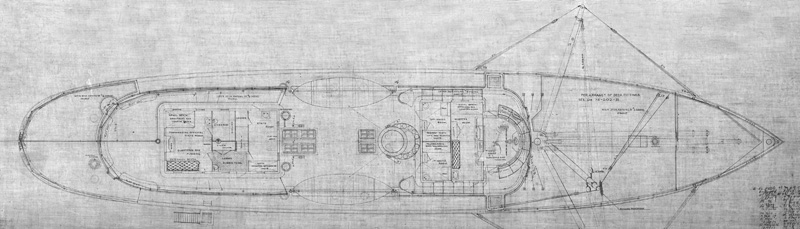

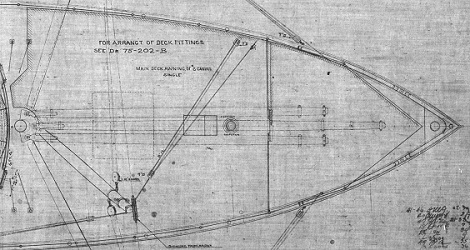

PLANS FOR THE GENERAL SAMUEL M. MILLS

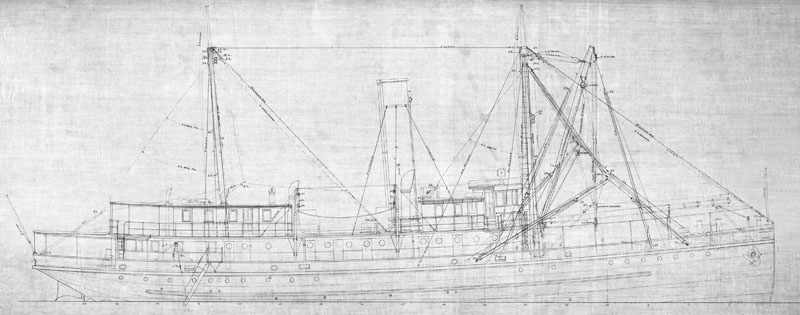

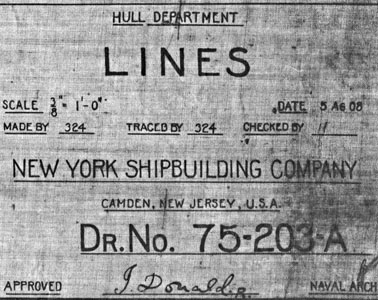

We have been able to locate the original New

York Ship Building Company August and September 1908 design drawings for the

General Samuel M. Mills and her two sister ships. Our illustrations come

from electronic scans of four huge brownprint drawings which measure 5-7

feet in length. Most of these plans were signed by registered Naval

Architect, "J. Donald."

All slices & CUs of Pequot Aerial photo next to plan details

(unless otherwise noted below) - - Calamaio family.

|

|

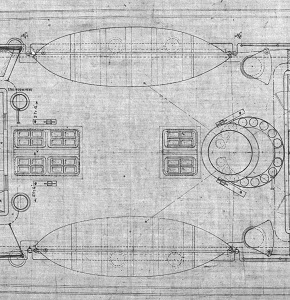

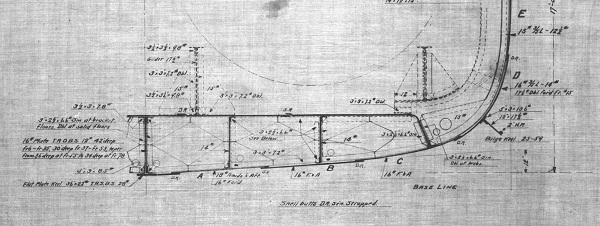

PLAN VIEW |

|

|

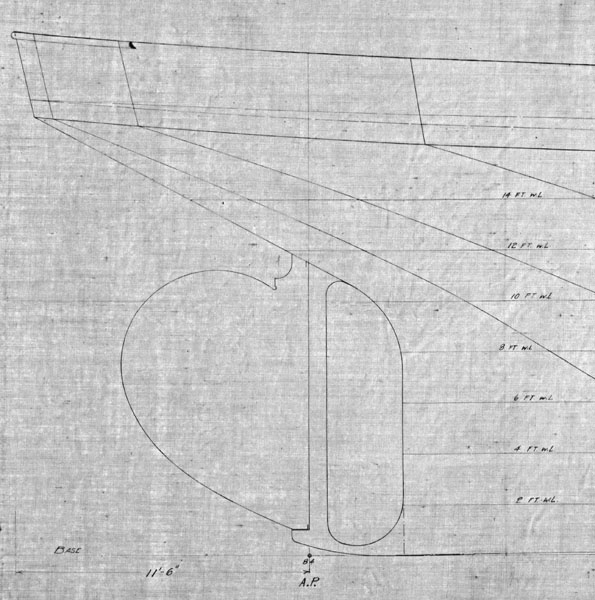

Here, in an elevation

view, we see half of the profile lines of the ship’s bow and half

of the profile of the stern. |

|

|

This detail of the stern and rudder uses two foot increments off the ship’s keel as a dimensional reference notated in feet of waterline “WL” above the keel. |

|

|

|

Here in ascending order, we see water line reference dimensions off the keel on the inverted plan view of the hull. |

The title block of the hull drawing labels this drawing as “LINES” and is signed off on by Naval Architect “J Donald”. |

The General Samuel M. Mills was launched from

Shipway K on Feb 13th 1909 and after outfitting was delivered to the Army on

March 19, 1909. We’ve learned that after commissioning the Mills

was stationed out of Fort Monroe, Virginia in 1910. During peacetime between World War I and World War II, the

Army maintained a fleet of eight mine planters. Four served along the East

Coast of the United States, two were stationed for duty along the West

Coast, and two mine planters took care of business in Hawaii, the

Philippines, and along the Panama Canal Zone.

|

|

|

|

(US Army

Quartermaster Foundation, |

Since the War Department’s Army contract for the ships Mills, Frank, and Schoenfield was executed by the Office of the Quartermaster General, a metal relief Quartermaster Corps Branch Insignia was mounted on the bow of each ship. This 1896 insignia with the eagle’s head down in front of the wing just ready to take off in flight, is different from the current version adopted in 1921.

|

|

The Mills and Schofield under construction in shipway K. We see two of the ship’s boilers hanging from the yard’s powerful 100 ton crane before installation. (Click to Enlarge). |

|

|

The Mills after launching in the shipway with her superstructure under construction |

|

|

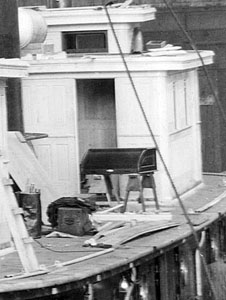

The framing in progress for the upper rear deck stateroom cabins where the ship’s senior officers were berthed. |

|

|

|

Here we can see a roll-top desk ready for installation in the Masters cabin behind the wheelhouse. A lifeboat is stored up in the cavernous space of the shipway ready for installation. |

|

|

|

This stern view of the Mills shows the upper cabin woodwork nearing completion as interior construction continues. (Click To Enlarge) |

In examining the contract and ship plans it is clear that the Submarine Mine

Service had two separate commands of officers and men aboard these ships.

The ship was run by a crew which consisted of 5 maritime officers, an

engineer and a crew of 18 sailors, while the mine planting mission was

carried out by Army troops which consisted of 3 commissioned artillery

officers, 3 non-commissioned officers, and 18 soldiers. So, as designed,

with a full complement of crew and troops 48 men would be aboard during mine

planting operations, compared to the 66 men aboard Pequot during WWII as

shown on the February 1945 crew list.

|

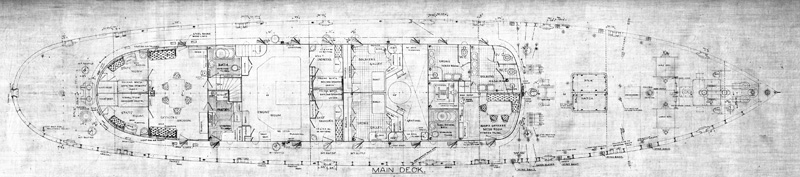

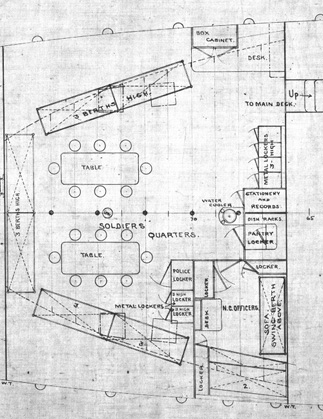

| Main Deck Plan View. Click image to enlarge. |

|

|

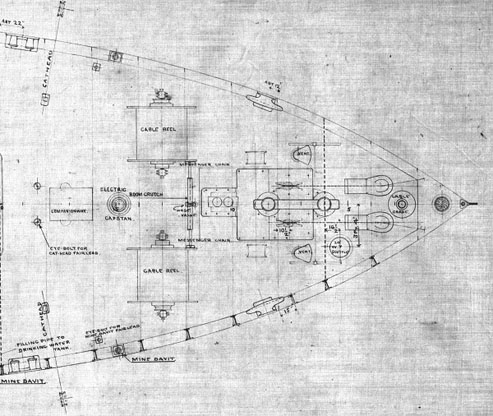

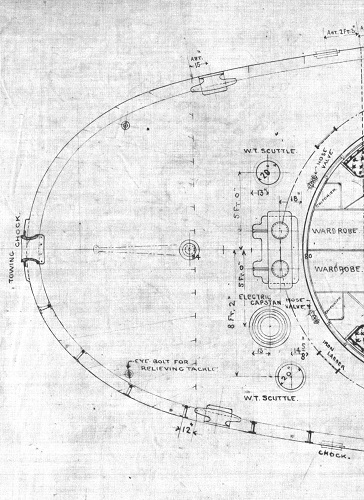

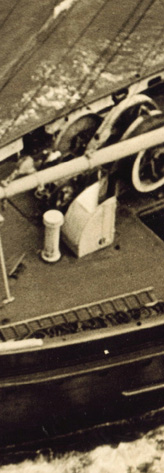

Up on the fo’castle deck we can see the large cable reels used for planting sea mines, air cowls, an electric capstan, lashing stanchions for mooring lines, and the anchor gear.

|

|

Directly in front

of the forward mast is the ship’s main hatch which is

where sea mines were

brought up from the lower hold and later where Pequot stored thousands of

feet of cable. We also can see the location of the main forward mast,

windlass equipment and a number of eye bolt locations to tie-off rigging

during mine planting operations.

As seen on the right, by the 1940s there was

only one hatch opening after the large cable winch was added.

|

In the forward cabins

on the main deck we see that the ship’s officers had their own upholstered

dining mess and small galley adjacent to an officer’s bath, and the Army

soldiers had their own washroom separate from the "head" used by the ship’s

sailors.

With the pilot house directly above these cabins, in

the center we see the Steering Engine used to control the ship’s rudder from

the helm above.

Pequot Chief Yeoman

Jim Hudlow writes that in the 1940s, "The enlisted men's mess room was on

the main deck at the place indicated on these plans as the 'Officers Mess

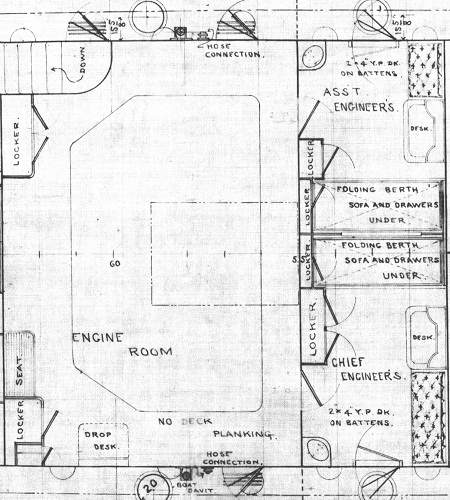

Room'." The two large

reciprocating engines which operated next to the boilers below protruded up

into the main deck’s engine room area.

The catwalk we see around the central opening

was called the Control Deck and it was provided with a desk and work area.

The ship’s Engineer and Assistant Engineer where housed in private

staterooms which opened directly onto this catwalk. We also see on the port

side an exterior doorway and stairs going down to the rear soldier’s

quarters. One can only imagine the noise level in this area.

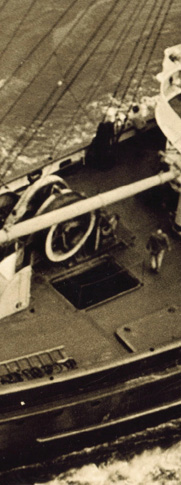

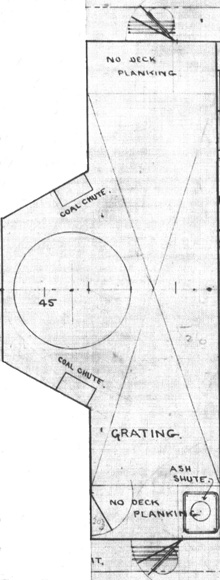

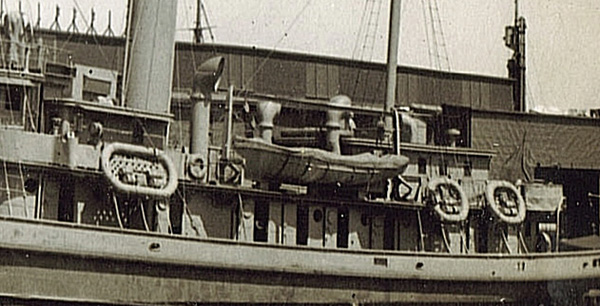

In this photo we can see doors on both sides of the

ship’s stack. The plans reveal that in front of the stack was an

enclosed passageway which provided access from both the port and

starboard side to two vertical chutes used to load coal into the bunkers

in the lower hold near the boilers. (Centre photo -

McCormack Family)

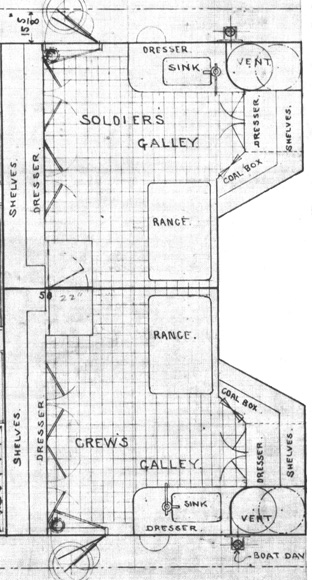

Behind the stack we see that the

ship was built with two completely separate galleys one for the ship’s

crew and one for the Army troops. This reinforces the assumption that

while aboard the Mills these two groups of men must have been fairly

segregated. Pequot seaman Mike Luongo tells us that that the

Pequot had just one Galley that ran the width of the main deck

cabin. A sailor can be seen in the entrance to the galley holding what

looks like a white coffee cup.

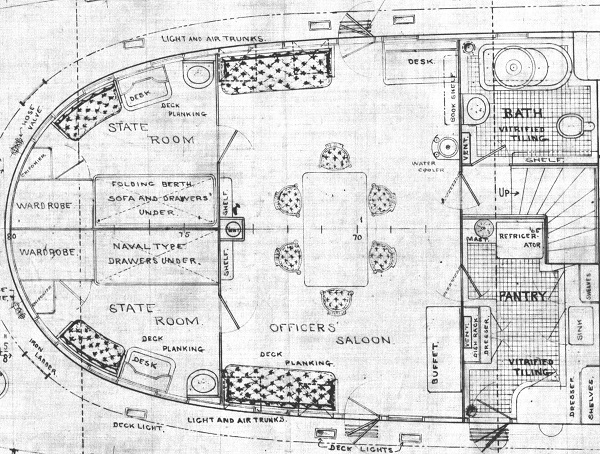

Here

we see that the rear cabins on the main deck were definitely “Officer’s

Country.” Two private staterooms are accessible from a large Officer’s Saloon

which has its own private pantry with a refrigerator and sink. There is also an

officer’s bath and shower which is also accessible from the command officer’s

staterooms above.

According to Seaman Mike Luongo the large "Officer's Saloon" cabin shown

here was used as a mess hall for the Pequot's crew during WWII. This was

the crew's meeting place where they would listen to the radio, play

cards, and write letters. They sat on benches with folding legs that

would be collapsed and stowed on top of the tables so the galley crew

could swab the deck after meals.

On the stern of the main deck we see the

large bracket or “chock” that could be used if the Mills ever had to tow

another ship. We also see the electric capstan and large stanchions used with

the large mooring lines which secured the ship to its dock while in port.

During WWII the small dory, in

which the crew used to set buoy markers when laying

indicator loop cables, was lashed on the stern deck.

(Photo - US Coast Guard Photo).

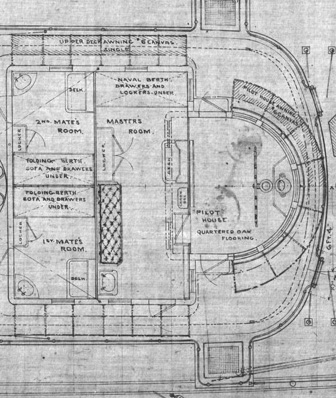

Upper Deck Plan View.

Click

image

to

enlarge.

The upper deck plan clearly shows

the stow locations of the three large boom arms on the main mast as well as

the outline of the large forward canvas awning which is seen in this 1933 photo of

Pequot.

(US Coast Guard Photo).

On second deck

level of the cabins containing the pilot house we can see the ship’s helm,

compass binnacle, and port and starboard flying bridges.

This was the business end of ship navigation and

per regulations the ship’s “Master” officer was bunked directly adjacent to

the pilot house.

We also see the 1st and 2nd

Mate were provided with small private staterooms.

By WWII we know that at least one of those

cabins was converted for the Pequot’s radio room,

and Mike Luongo tells us that the other Mate’s Room was the Pequot’s

pharmacy and sick bay. “One New Years Eve about 10 guys got together and we

raided the pharmacy of some 190 proof alcohol and we spiked our Coke’s with

it,” Mike remembers.

(Click to Enlarge)

The curving forward

windows of the pilothouse and the sides of

these cabins were shaded with canvas awnings. It

also looks like a construction foreman’s coffee cup in 1909 may have spilled

over onto this drawing. Pequot Chief Yeoman Jim Hudlow writes,

"The ship's office was on the same level as the pilot house. We had four

office workers and the office was not big enough for all of us." We can

also see that by the 1940s a metal stairway from the fo'castle deck up

to the pilot house and upper forward cabins was added. Those stairs, which

we see in so many Pequot era photos, was not originally built with the ship.

|

|

|

Between the two upper deck cabins was the lifeboat deck where behind the stack two full size lifeboats were always ready and provisioned for emergencies. We also see the skylights over the galleys and engine room below. To the right are the two large air cowls which provided air to the ship’s boilers three decks below.

|

During World War II with almost 70 men aboard, in addition to the two main lifeboats, six large web bottom life rafts with provisions were lashed to the Pequot, three on the port, and three on the starboard sides of the ship. Below the rafts we can see the metal guides going down to the gunwale which would be used to slide them into the sea. An additional life raft was lashed to the top of the upper rear deck cabins.

|

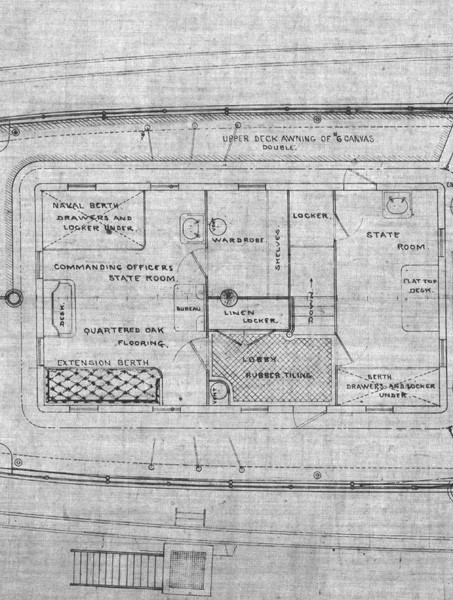

In the upper rear cabin we see the Commanding Officer’s stateroom which is accessed from a small lobby area which also leads to a second ample state room most likely for the command officer of the Army troops. The ship’s captain was provided a full size bed, sink, desk, bureau of drawers and an upholstered couch which could double as a 2nd berth. Private stairs from these two staterooms lead down to the officer’s bath below.

|

|

Both sides of this cabin and the fantail deck behind it were covered by a canvas awning. During WWII the awning was removed and this upper rear deck held the two 20mm Oerlikon anti-aircraft guns and ammunition ready boxes. (US Coast Guard Photo).

|

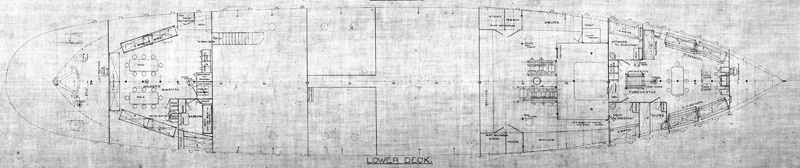

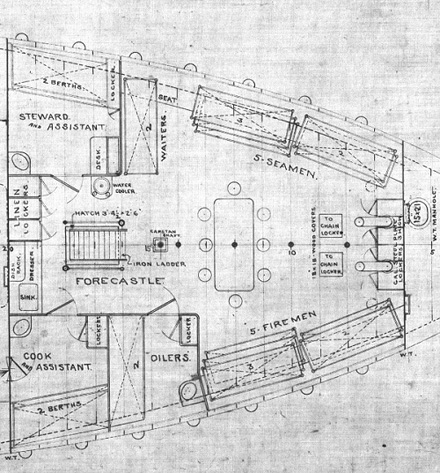

| Lower Deck Plan View. Click image to enlarge. |

|

|

| (Click to enlarge) |

|

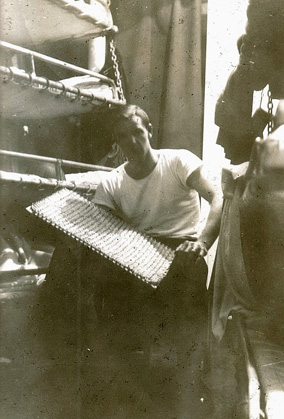

In the only WWII era photo we have of the crew quarters we

see on both sides of George Simmons that bunks are stacked 4 high, about 30"

apart and that the space between the row of berths looks about 3' wide.

Seaman Mike Luongo remembers that "The main

crew sleeping quarters was in the forward part of the ship. It had bunks 4

high with 4 rows on one side and 4 on the other." Jim Hudlow,

Pequot Chief Yeoman writes, "The

enlisted men's living quarters was on the lower deck up forward. There was a

small walled section in this area for Chief Petty Officers. I had a bunk in

the chief's section." Mike Luongo adds, “Yea, we slept four high

and it was all based upon seniority. When you first came aboard you got the

last bunk in the back by the maintenance room and carpenter's shop. That’s

where the cold air from outside came down into the hold. Whenever some guy

got transferred everybody would move. We’d wrap our mattress around our

seabag and shift bunks. The best spot was the top bunk all the way forward

up at the bow. I eventually ended up there!” (Mike Luongo photo).

|

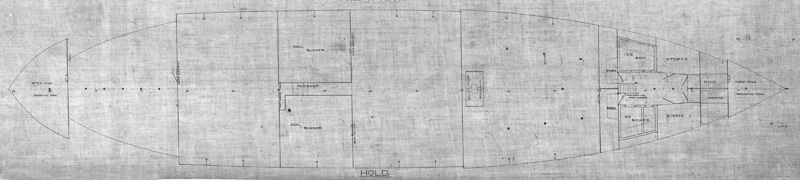

Behind the rear fo’castle bulkhead was the ship’s main hold where sea mines were stored. Here we see the motorized port and starboard drums on both sides of the main forward mast which controlled the three large boom arms used during mine planting operations and to hoist deadly sea mines up to the fo’castle deck above. Against both sides of the hull we see other storage areas which were probably used to stow gear and expendables. After conversion to a cable ship this area was modified to serve as the Pequot’s large cable hold.

|

| (Click to enlarge) |

The aft end of the lower deck was designed as the

Soldiers quarters for the Army Troops. Here we see a small private

compartment for non-commissioned officers with two berths against the hull

and one berth as a swinging hammock above a sofa.

Two tables with chairs, a water cooler, sink,

and small pantry are provided along with what appears to be lockers for

small arms.

Based upon the number of berths shown this area

was designed to sleep 21 soldiers.

|

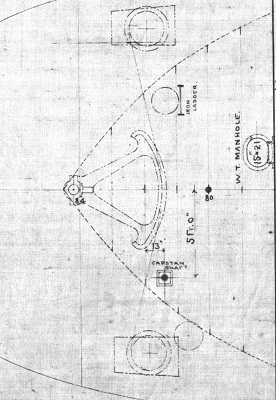

Aft of

the Soldiers Quarters we see details of the two capstans that operated

the Steering Quadrant which controlled the ship’s rudder from the

forward steering engine.

|

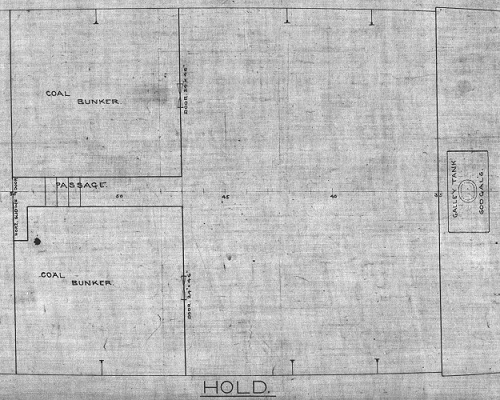

| Lower Hold Plan View. Click image to enlarge. |

Mike Luongo tells us that in addition to cable, in the large hold between the engine room and the forward crew quarters there was a carpenters shop and storage for cleaning supplies. “That’s also were they kept everything we used on painting duty. We had chipping hammers, paint, brushes and scrapers.”

|

In the far forward lower hold we see the lockers for

the ship’s two anchor chains, large refrigerated storage coolers as well as

other food storage compartments. A trimming tank is seen far forward which

could be filled with sea water as needed if the ship was too light at the bow.

Seaman Mike Luongo explains that, “Whenever we went out to sea they made

sure we had enough supplies and they were all stored down below. We formed

a human chain gang down through the fo’castle to the refrigerators down

there to stock up. We also had a freezer for frozen food and meats. We

always had enough provisions for at least two weeks at sea.”

|

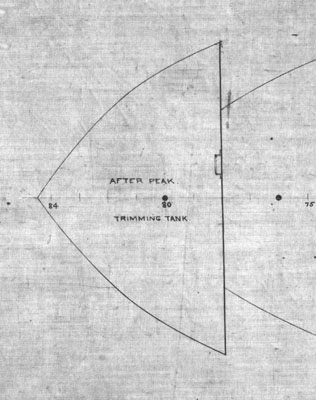

|

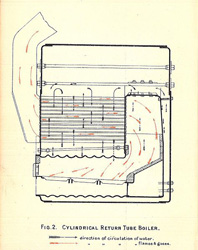

Although these plans do not provide

details on the placement of the ship’s boilers and engines, here we see two

large coal bunkers which could hold 128 tons of coal and the location of the 600

gallon fresh water tank which would weigh 5010 lbs or 2.5 tons when full. When

we include the 2-3 tons of cable that could be stored in the forward hold and

other supplies, when the Pequot left port she had close to 135 tons of

expendables aboard. In addition to the trim tank at the bow we see that a rear

or “After Peak” trimming tank was located at the stern. These fore and aft

trimming tanks would be filled with seawater as needed to keep the ship riding

level at sea. As coal was burned, water was consumed, and cable was laid, weight

would be reduced in different sections of the lower hold and by adding or

draining water from these tanks the ship’s trim could be kept in balance. Mike

Luongo tells us that water was rationed. “When we were out at sea we could only

take a shower every third day. When we were in port you could have a shower any

time you wanted to.”

|

|

|

One of the "General" Army mine planters preparing to lower a mine into the sea, possibly the Mills. Here we can clearly see the three large forward booms off the main mast in use during this delicate operation. (Photo courtesy Ramon Jackson from the Coast Artillery Journal, May 1926) |

A sea mine of the era being hoisted on davits ready for planting by an Army mine planter. (Coast Defense Study Group, Inc.). |

|

|

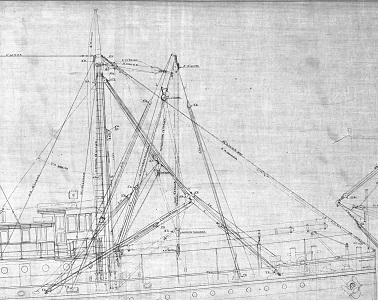

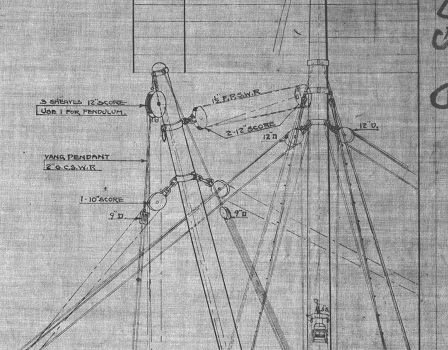

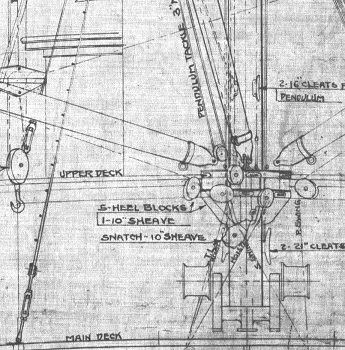

As seen in these details the operation of the three boom arms required very sophisticated rope and pulley rigging as well as the use of motorized winch drums on the upper and lower decks.

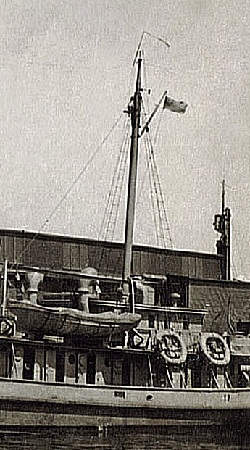

The Changing Masts

Over the years the ship’s forward mast was completely re-configured a number

of times based upon mission needs as an Army mine planter and a Coast Guard

cable layer. In addition to rigging and rope ladders many of the lines we see on

the ship’s mast were antennas for the various generations of short and long wave

radio transmitters and receivers installed as communication technology advanced.

|

|

|

|

| 1909 | 1927 | 1943 | 1944 - 1947 |

|

(Photos Left to Right - US Naval Institute, US Coast Guard, Calamaio Family, Lou Carhart) |

|||

When originally constructed as an Army mine planter the ship had three large forward booms and there was no yard arm on the forward mast. The rope and cable ladders, or “rat lines,” crew members could climb up were installed on the port and starboard sides to permit servicing of the pulley and rigging system needed for the forward booms.

By 1927, after conversion to a cable ship in 1922, two of the large forward booms were removed, additional running lights were added, and an upper yard arm was installed near the top of the mast for radio antennas. It appears the height of the mast was increased and a cross member for radio antenna wires which ran to the rear mast was suspended by cables behind the forward mast. In addition to mast mounted lights three vertical cable work indicator lights or pendants are seen suspended from the upper yard arm. By 1943 those units are no longer present and the radio antenna cross member has been removed during WWII. We see in the May 1944 photos of Pequot, that the ship’s mast was reduced in size and a longer yard arm was installed to accommodate the newest generation of radio and radar antennas.

|

|

|

| 1909 | 1927 | May 1944 |

|

(Photos Left to Right – Independence Seaport Museum, US Coast Guard, Lou Carhart) |

||

|

“It is requested that the Navy Yard, Boston, remove topmast of PEQUOT mainmast together with shortstays, etcetera, this to include the reducing in size of the jackstaff. In removing the topmast it is also requested that the radio antenna be installed at the highest possible point between the fore and mainmast.” |

|

|

|

A WWII Pequot sailor up on the ratlines servicing the running lights and a profile of the rear mast before the 1942 reductions. (Both McCormack Family) |

|

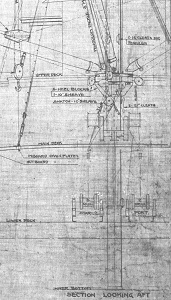

|

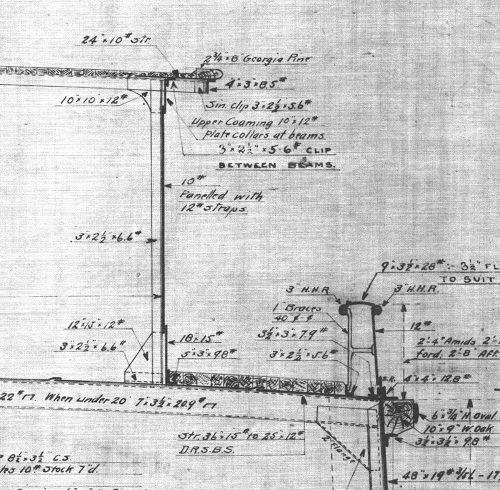

This cross section detail shows the ship's

keel and the honeycomb

design of the ship's strong double bottom

hull.

|

Here we see the wooden decking and a cross section of the gunwale which rose 28" amidships.

Go to Part Two to learn more about five of the Pequot’s “Sister Ships” and their construction Click here

|

|

|

|

Joyner Library Special Collections, East Carolina University |

||

Special Thanks to Ramon Jackson.

For more information on the history of the Coast Artillery Corps and the Army

Mine Planter Service see:

http://patriot.net/~eastlnd2/army-amps.htm

Special Thanks also to Matt Herbison at the Independence Seaport Museum for locating these construction photos for us.

Every effort has been made to trace and acknowledge copyright. The authors would welcome any information from people who believe their photos have been used without due credit. Some photos have been retouched to remove imperfections but otherwise they are true to the original.

FEEDBACK

If you have comments or queries specifically

about the Pequot or her Sister Ships, please contact

Chip Calamaio

chipaz@cox.net, 938 E. San Miguel Avenue, Phoenix, 85014, Arizona,

USA. (H) 602-279-4505.

Click here to go to the Pequot Main Page.

Research and design: Chip Calamaio and Richard Walding